Phasics

- Wavefront, MTF and QPI measurement solutions

- Products

- Applications

- Markets

- Company

- Contact us

Lithography systems for the semiconductor industry rely on extremely complex laser sources and optical systems. The Phasics SID4 range spans from the ultraviolet (UV) to the longwave infrared (LWIR) and has been proven extremely valuable in the semiconductor industry for the qualification of such optical systems at their designed wavelength. Engineers in research and development or manufacturing use the SID4 wavefront sensors for laser sources and optical systems alignment and metrology.

The Phasics SID4 UV wavefront sensors give access to a complete laser characterization in a single measurement. SID4 UV wavefront sensors are the ideal tool to support lithography system manufacturers and integrators to align, qualify, and monitor their ultra-violet sources and systems.

Control of the laser quality and beam shaping with adaptive optics is applicable to lithography machines. The combination of SID4's unique wavefront sensor, OASys expert adaptive optics software, and dedicated deformable mirrors represent a robust solution for lithography machine manufacturers.

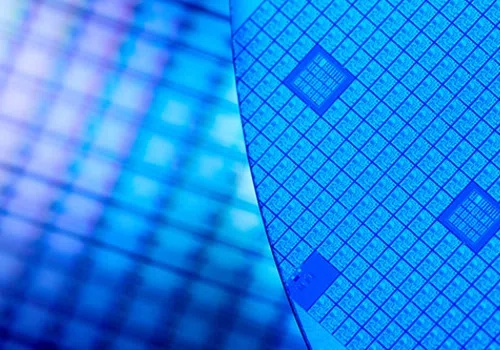

All along the lithography process, inspection of the wafers is performed. Inspection is a key part in the wafer manufacturing process. Coupling high dynamic range, nanometric wavefront sensitivities, and high resolution, Phasics' technology is a great candidate to be integrated in wafer inspection machines.