Optical components & assemblies

Broad range of optical testing systems

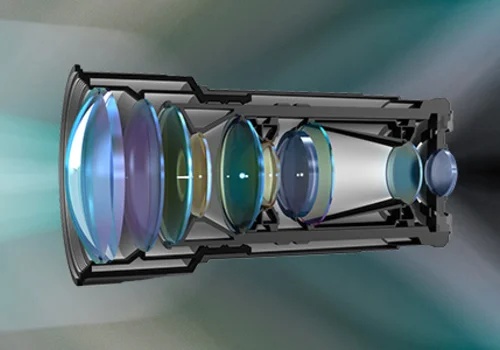

Modern optical design and assembly benefit from tremendous innovation in manufacturing technologies: CNC and molding pave the way to complex freeform shapes, high-index materials reduce form factors, and multi-layer coatings bring customized spectral response. High-resolution wavefront sensing helps R&D and QA engineers to meet all measurement challenges from optical design to final assembly.

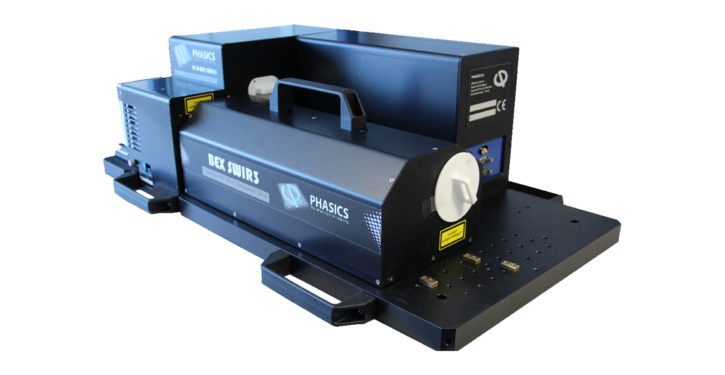

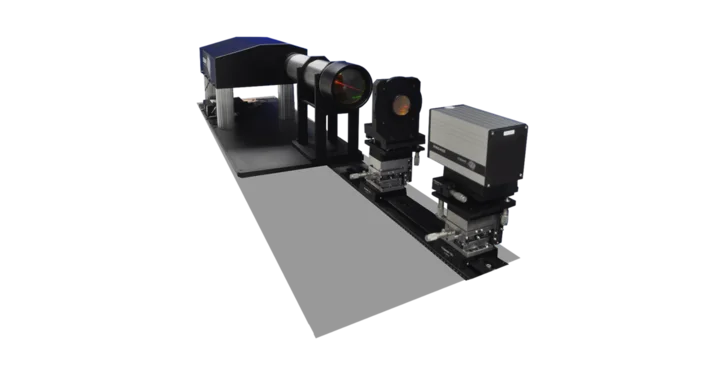

Optical system assembly metrology

Complex optical assemblies require precise control of each component. Combining high-resolution and high-dynamics, the SID4 wavefront sensors and Phasics metrology stations are perfectly suited to characterize such components either in single or double pass.

Downloads

Download

Related Products

订阅Phasics资讯获取最新信息

Join us on Wechat